Menu

Machinery Group Mobin Sanat

mobinsanaat

Mobin Sanat Machinery Group

Mobin Sanaat machinery group has been operating since 1985 with the production of industrial machinery in the field of food, this group has been able to have significant successes in the manufacture of various types of food, pharmaceutical, chemical and industrial machinery using the latest technologies and valuable experiences of engineers and skilled personnel and take an effective step in improving the process of domestic production.

- contact us 09135880300

- location itan esfahan

Design and production of food industry production line machines

our services

Counseling

- Production line

- layout Required devices suitable for production and assembly

- Product processing formulation

Design and manufacture of machines

- According to the needs of the collection

- Solving production line problems

- Optimizing the production process

support services

- Installation

- Timely service

- Overhauling worn out devices

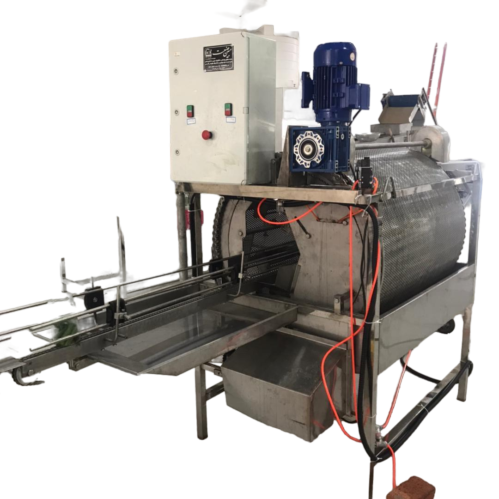

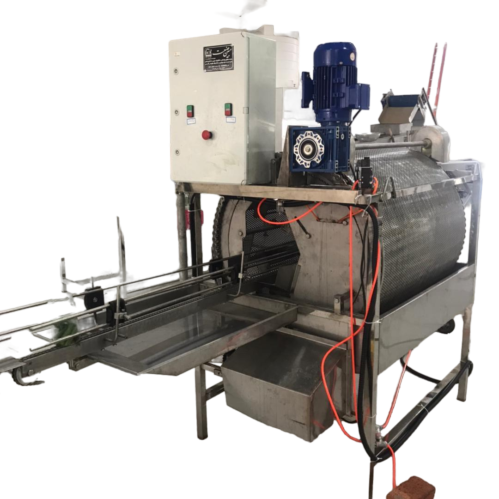

The blanchers crew.

The Blancher is fully automatic and operates with a power and steam system. It is used to dye pickles and cook raw materials such as cauliflower, pearl garlic, olives, carrots, shallots, eggplants and other ingredients. The tank of the Blancher device is built slopping, which during washing directs the remaining particles to the outlet of the device’s sewer. It has an inlet for water and a fine outlet. Its inlet vapor is indirect and has a coil that prevents energy waste, which directs the product to the outlet through a rotating system.

Pasteurizer tunnel

A pasteurizer tunnel is a large stainless steel compartment or channel used to carry out the process of sterilization food products. The dimensions and technical specifications of the pasteurizer tunnel are determined by the production capacity and the type of product in question. The pasteurizer tunnel is one of the key machines in the packaging line of tomato paste, pickled cucumbers, pickles, olives and drinks.

jar filling machine

This machine is used in the category of bulk filling machines for mixed pickles, pickled cucumbers, olives, pearl garlic, halopino pepper, okra, mushrooms and such products. The device is equipped with a vibrator pneumatic embedded in the jar transfer rail, a pneumatic jack embedded in the material discharge tray and inverters to adjust the speed of the container transfer chain (jars, cans and packets) and the rotation speed of the main drum to adjust the output speed and the same volume of product in the jar.

Mushroom sorting machine

This machine is designed and manufactured for separating mushrooms in several different sizes depending on the needs and order of the customer. It has PVC tape, Teflon rollers, steel profile chassis and steel sheet covers. it has a mechanical vibrator for better separation.

Can filler machine

The can filler machine made by the industry-based machinery group is used to fill cans with Seventeen kilos or bags of twenty to thirty kilograms for a variety of products such as pickles, blanched mushrooms, olives and frozen vegetables.

Mobin Machinery Group, industrial equipment production industry in the field of food

, this group has been able to have significant successes in the manufacture of various types of food, pharmaceutical, chemical and industrial machinery using the latest technologies and valuable experiences of engineers and skilled personnel and take an effective step in improving the process of domestic production.

our customers

Contact us